Continuous Emission Monitoring System (CEMS)

Simultaneous measurement of up to 14 components in flue gas. The Fuji CEMS gas analysis systems allow the continuous monitoring of gas emissions in flue gases from natural gas, fuel, coal, industrial or urban waste combustion, such as: CO - CO2 - NOX - N2O - NH3 - HCI - CH4 - O2 - H2O PRESSURE - TEMPERATURE - FLOW - DUST

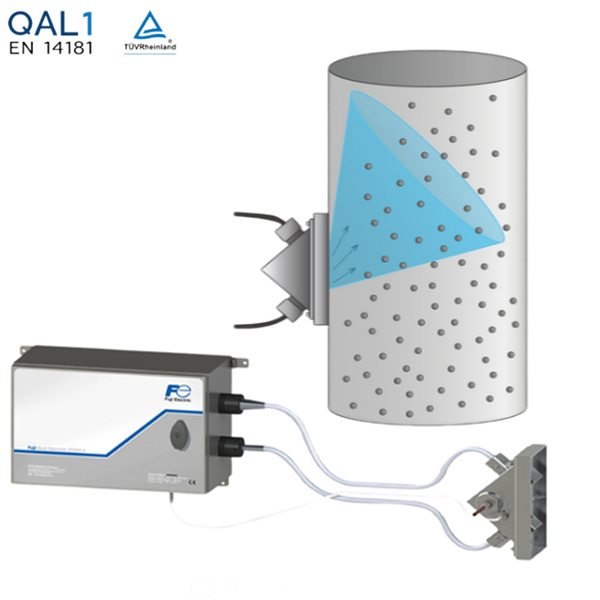

Flue Gas Dust Monitor

Robust and accurate back scattering dust monitor for rough industrial installations

QAL1 certified continuous monitoring of particulates concentration. Thanks to the backscattering technology, the LED light beam provides an accurate measurement (insensitive to ambient light). Continuous particulates emissions monitoring - Coal, biomass, and other solid fuels fired boilers - Oil fired boilers, diesel engines

Extractive infrared multigas analyzers NDIR

Measurement of the concentration of 1 to 5 components

The Fuji Electric extractive multigas analyser range consists of non-dispersive 5-gas infrared analyzers. They allow simultaneous and continuous measurement by extraction of 1 to 5 gases from: CO, CO2, NOx, SO2, CH4 and N2O by single or double beam NDIR technology O2 by paramagnetic, Zirconia or electrochemical technology.

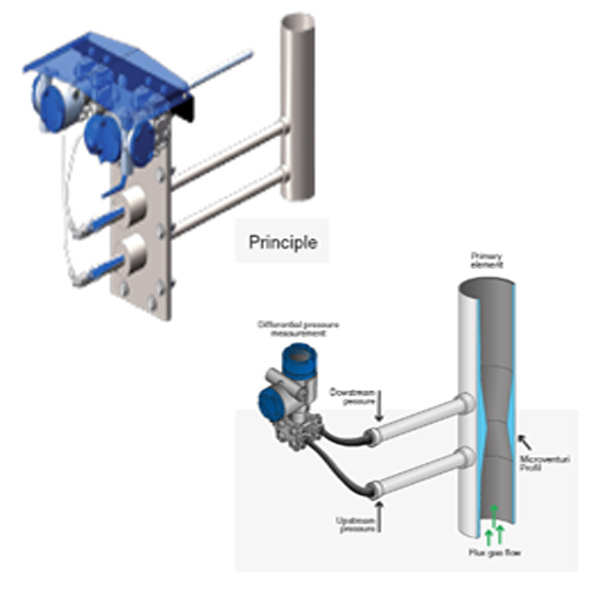

Flue Gas Flow Rate Monitors

Microventuri based continuous monitoring

of flue gas flow rate, pressure and temperature

Designed for tough industrial applications

with highly dusts loaded fl ue gas.

FLOW - PRESSURE - TEMPERATURE

ZrO2 Extractive Analyser

Controlled by Fuji Electric multigas analysers ZRE or ZKJ

Very long life zirconia sensor, perfect stability Adapted to severe environment conditions such as shocks and vibrations.

Laser Gas Analysers

Insertion type offers high-speed measurement.

Long-term stability and low maintenance. ZSS Laser Gas Analysers for : waste incinerators, district heating and industrial boilers, chemical plant.

NH3 - HCI - CO - O2 - CO2 - CH4

NOx Converters - Exhaust gas monitoring

High NO2 to NO conversion efficient catalyst.

Compact, easy to install and catalyst easy to replace. Combustion plants, incineration, steel plants, furnace control, CEMS, research labs.

In-situ zirconia oxygen gas analysers

Optimization of combustion efficiency and compliance with environmental standards Ideal for combustion control in boilers, incinerators and furnaces. The analyser makes use of the property of zirconium oxide that conducts oxygen ion when heated.

Biogas Analyser System ZPSB

Reliable: Equipped with the latest Fuji Electric NDIR technology and specific cross-interference treatment of biogas components, CH4 monitoring is accurate and reliable thanks to state-of-the-art microflow gas detectors.

Analyser O2 flameproof type,TIIS and NEPSI certified

This in situ oxygen gas analyser is specially designed for continuous measurement of oxygen concentration in noncombustible exhaust gas.

Ideally for combustion management and control. This analysis system comprises the detector and the converter coupled together.

Gas sampling device not required Fast- response (4–7 seconds)

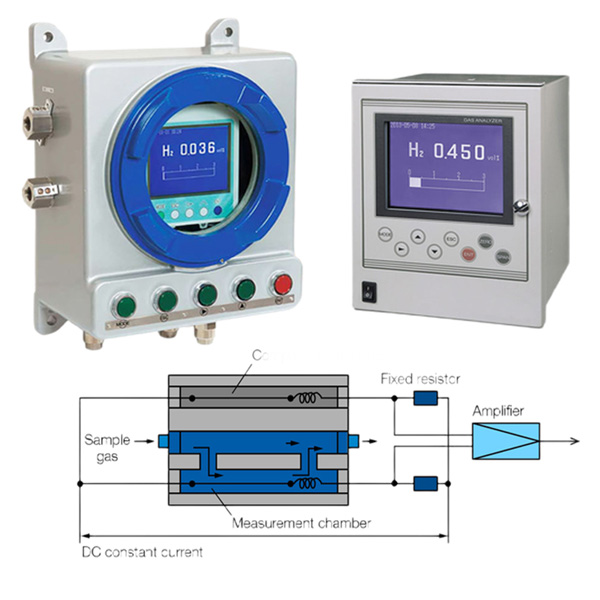

Thermal Conductivity Gas Analyser ZAF and ZAFE

eliable process control for furnaces, metal industry, semiconductor and gas separation.

The analyser continuously measures the concentration of gases such as H2, He, and Ar with high stability.

It is also available in a version for hazardous areas (for countries outside the European Union): ZAFE certified Ex NEPSI.